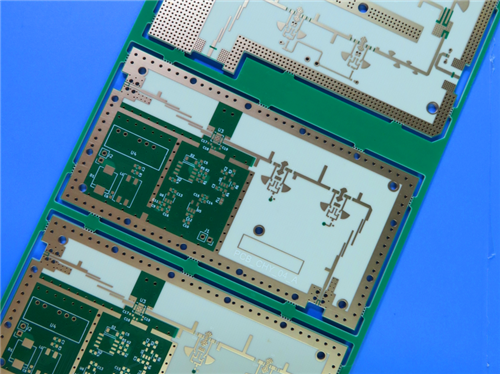

High Frequency 6-Layer Hybrid PCB RO4350B and S1000-2M with ENIG Finish

1.Introduction & Material Technology

RO4350B High-Frequency Material

Rogers RO4350B is a proprietary woven glass reinforced hydrocarbon/ceramic laminate offering:

Electrical performance approaching PTFE/woven glass

Standard epoxy/glass manufacturability

Cost-effective alternative to traditional microwave laminates

UL 94 V-0 rating for high-power RF designs

Key advantages:

Tight dielectric constant (Dk) control

Excellent dimensional stability (CTE matched to copper)

Reliable plated through-holes in thermal shock conditions

High Tg >280°C for stable processing

S1000-2M High-Performance Material

Complementary material providing:

Improved through-hole reliability with lower Z-axis CTE

Superior mechanical processability

Lead-free compatibility

Excellent anti-CAF performance

UV blocking/AOI compatibility

2.Key Material Properties

Key Material Properties(RO4350B)

Dielectric Constant of DK 3.48 +/-0.05 at 10GHz/23°C

Dissipation Factor of 0.0037 at 10GHz/23°C

Thermal Conductivity 0.69 W/m/°K

X axis CTE of 10 ppm/°C, Y CTE of 12 ppm/°C, Z CTE of 32 ppm/°C

High Tg value of >280 °C

Low water absorption of 0.06%

(S1000-2M)

Lower Z-Axis CTE for improved throughhole reliability

Excellent Mechanical Processability andThermal Resistance

Leadfree Compatible

Tg180℃ (DSC), UV Blocking/AOI compatible

High heat resistance

Excellent Anti-CAF performance

Low water absorption

3.Complete PCB Specifications

Construction Details

| Parameter | Specification |

|---|---|

| Base Materials | RO4350B + S1000-2M |

| Layer Count | 6 layers |

| Dimensions | 76.5×83mm (±0.15mm) |

| Thickness | 1.5mm |

| Trace/Space | 4/4 mils |

| Hole Size | 0.3mm (min) |

| Via Types | Blind (L1-L2) |

| Copper Weight | 1oz (35µm) all layers |

| Via Plating | 20µm |

| Surface Finish | ENIG |

| Solder Mask | Blue (both sides) |

| Silkscreen | White (both sides) |

| Impedance Control | 50Ω (4mil top layer) |

| Electrical Test | 100% tested |

4.PCB Stackup: 6-layer rigid PCB

| Layer | Material/Type | Thickness | Dielectric Constant | Notes |

|---|---|---|---|---|

| L1 | Copper (Top Layer) | 35 μm | - | Signal layer, ENIG finish |

| RO4350B | 0.254 mm | 3.48 @ 10GHz | Core material | |

| L2 | Copper (Inner Layer 1) | 35 μm | - | Power/Ground plane |

| Prepreg (1080 X2 RC63%) | 0.127 mm | 3.4 (typical) | Bonding layer | |

| L3 | Copper (Inner Layer 2) | 35 μm | - | Signal layer |

| S1000-2M | 0.254 mm | 3.2 (typical) | Core material | |

| L4 | Copper (Inner Layer 3) | 35 μm | - | Power/Ground plane |

| Prepreg (1080 X2 RC63%) | 0.127 mm | 3.4 (typical) | Bonding layer | |

| L5 | Copper (Inner Layer 4) | 35 μm | - | Signal layer |

| RO4350B | 0.254 mm | 3.48 @ 10GHz | Core material | |

| L6 | Copper (Bottom Layer) | 35 μm | - | Signal layer, ENIG finish |

5.Board Statistics

Components: 149

Total Pads: 215

Thru Hole Pads: 57

Top SMT Pads: 38

Bottom SMT Pads: 120

Vias: 79

Nets: 6

6.Manufacturing & Quality Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class 2

Via Types: Through-hole only (no blind vias)

Availability: Worldwide shipping

7.Target Applications

Commercial airline broadband antennas

Microstrip and stripline circuits

Millimeter wave applications

Radar and guidance systems

Point-to-point digital radio antennas

High-frequency communication systems

8.Material Combination Benefits

The hybrid construction combines:

RO4350B's superior high-frequency performance

S1000-2M's mechanical reliability

Balanced CTE for dimensional stability

Cost-effective multilayer solution